Pulse Vacuum Horizontal Type Sterilizer Atuocalve Sterilizer

1. Sterilizing course automatic sterilization controlled by computer, easy to operate.

2. With drying function, suitable dressing drying.

3. With over-temperature, over-pressure auto-protect device.

4. The door opening mechanism cannot be operated until the pressure in the chamber is reduced to 0.027MPa. It can’t be start on if the doesn’t closed well.

5. The safety value will be open automatically when the inner pressure over 0.24MPa, and the steam be exhausting to the water tank.

6. The power will be cut-off automatically, cut-off the water and alarm when the machine lacking water.

7. The chamber of the sterilizer is made of stainless steel.

8. Touch screen color display and with printer.

9. With vacuum pump

Requirements for Autoclaving(time and Temperature)

Autoclave Sterilization

In healthcare and industrial settings, autoclaves, also known as steam sterilizers, are used to eliminate harmful bacteria, viruses, fungi, and spores by subjecting items placed in a pressure vessel to high temperatures. The items are heated to the appropriate sterilization temperature and held at that temperature for a specific duration. The moisture in the steam efficiently transfers heat to the items, affecting bacteria and spores.

The medical profession refers to steam sterilizers as "autoclaves" and sets specific parameters and requirements for successful autoclaving, including the use of a suitable biological indicator in the sterilization process.

Requirements for Autoclaving

Autoclaving requires the manipulation of four primary parameters to achieve successful sterilization: steam, pressure, temperature, and time. Manipulating these parameters allows for different cycle setups to sterilize various types of loads.

Pressure and Steam

Effective steam sterilization requires dry saturated steam with a dryness fraction of ≥97% to ensure significant heat transfer. High pressure allows for more rapid microbial kill by achieving high temperatures.

Temperature

Temperature is crucial for microbicidal activity, typically ranging from 121°C (250°F) to 132°C (270°F) during steam sterilization. Maintaining these temperatures for a minimum period is essential for eliminating unwanted microbes.

Time

Different types of items require varying sterilization times, influenced by factors such as the item's material, packaging, and type of sterilizer used. Adhering to the required time is essential for practical sterilization.

Time and Temperature in Autoclaving

When designing or upgrading an autoclave, it's crucial to consider temperature and time requirements, as they control the rate and depth of sterilization. Meeting these conditions is vital for sterile processing using autoclaves.

In gravity autoclaving, the minimum sterilizing conditions are 121°C (250°F) for 15 minutes using saturated steam at a minimum pressure of 15 psi. For a pre-vacuum sterilizer, the minimum sterilizing condition is 132°C (270°F) for 4 minutes. Extending the cycle time is recommended based on the load composition to ensure complete microbial elimination.

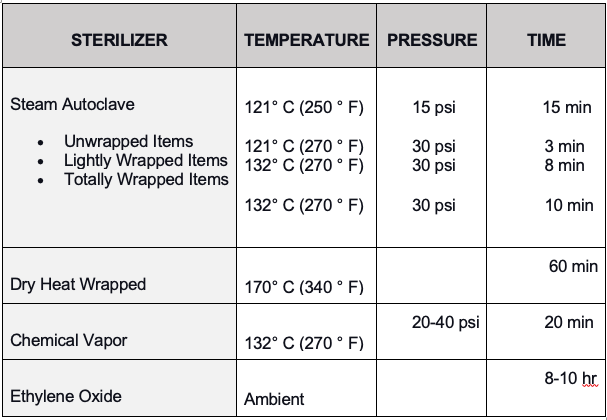

Understanding the temperature and time requirements during the sterilization process is crucial for selecting suitable equipment and ensuring its proper function. Below is a chart illustrating various time and temperature requirements during autoclaving and other processes:

Understanding these aspects beforehand can help in making informed equipment purchases and ensuring proper functioning.