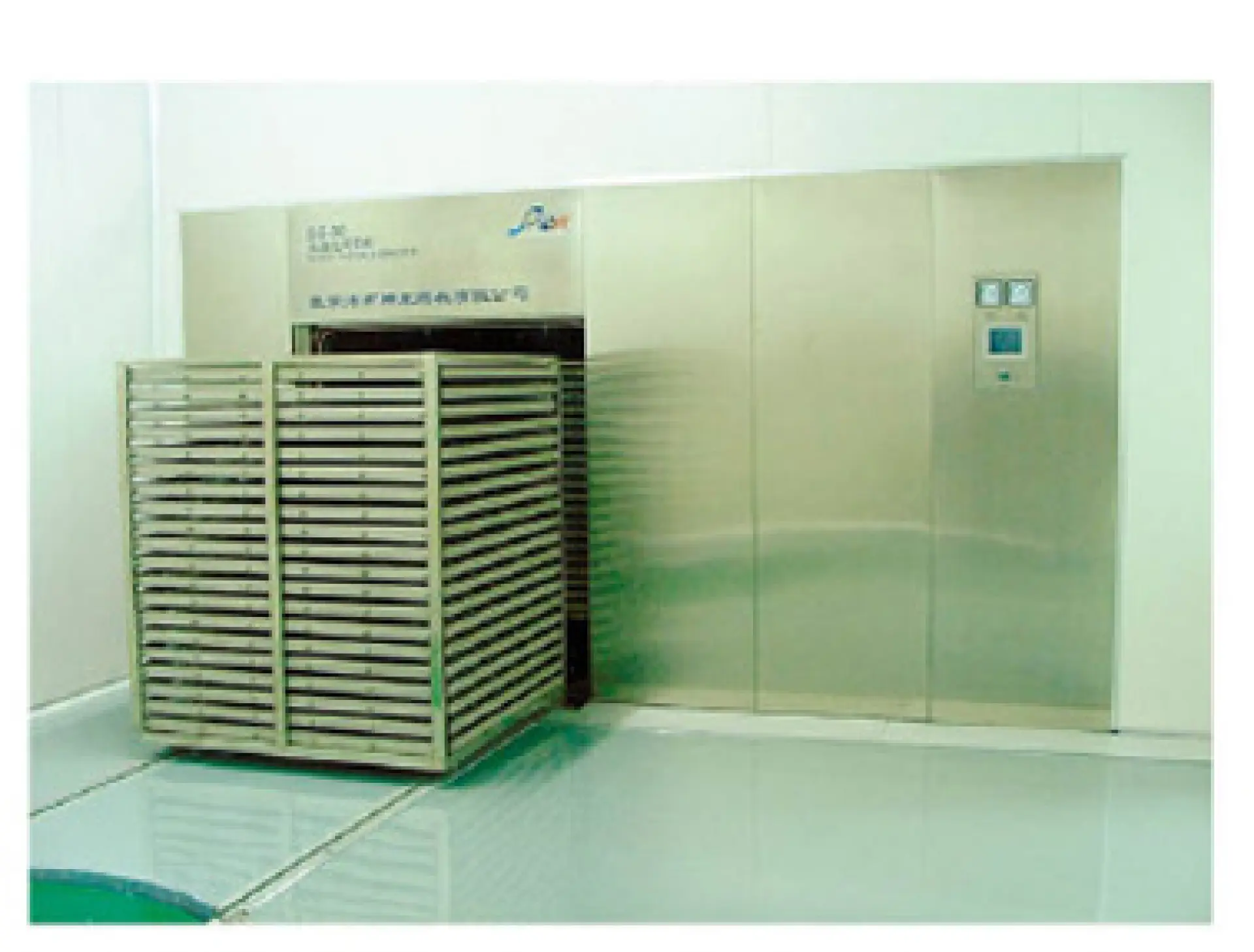

Superheated Water Shower Sterilizer

This series adopts cyclical water as a sterilization heating carrier and carrier and carry and carry out water-pouring sterilizing operations for articles.

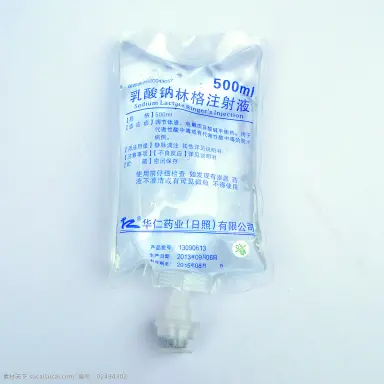

During the whole working course, superheated water operates in a relatively sealing cyclical system, which has a series of advantages, high heat efficiency, good temperature evenness, stable temperature adjusting range, etc. Besides, this equipment also effectively, good temperature evenness.stable temperature adjusting range, etc. Besides, this equipment also effectively prevents second pollution during working with an anti-pressure protection device. lt can be applied widely to high-and-low temperature sterilizing operations on liquid in glass bottles. Ampoule bottles, plastic bottles, plastic packs, etc, in pharmaceutics.it is also suitable for the foodstuff industry to sterilize all kinds of sealing packages, drinks, and cans.

| Main Parameters and Utilties | |||

| Design Pressure | 0.245Mpa | Steam Pressure | 0.4-0.6Mpa |

| Working Pressure | 0.22Mpa | Tap Water Pressure | 0.2-0.3Mpa |

| Design Temperature | 139℃ | Compressed Air Pressure | 0.6-0.8Mpa |

| Working Temperature | 60-134℃ | Pure Water Pressure | 0.2-0.3Mpa |

| Heat Equiibrium | ≤±1℃ | ||

Overal Size L×W×H(mm) |

Chamber Size L×W×H(mm) |

Steam Consumption (kg/cycle) |

Wae (kg/cycle |

Compressed Air (kg/cycle) |

Cooling Water (kg/cycle) |

Loading Cart(pcs) |

power supply | Net Weight (kg) |

|

| SG-1.2 | 1820×2500×2000 | 1500×750×1100 | 80 | 100 | 2.0 | 2000 | 2 | 5 | 2150 |

| SG-2.5 | 3320×2500×2000 | 3000×750×1100 | 130 | 200 | 4.0 | 4000 | 5 | 3100 | |

| SG-5 | 3780×3150×2250 | 3400×1000×1500 | 250 | 450 | 10.0 | 8500 | 8 | 5500 | |

| SG-13 | 4580×4000×2820 | 2000×4200 | 580 | 1000 | 25.0 | 9000 | 4 | 15 | 8500 |

| SG-26 | 8580×4000×2820 | 2000×8200 | 1200 | 1500 | 40.0 | 16000 | 8 | 25 | 18000 |

| SG-32 | 10580×4000×2820 | 2000×10200 | 1400 | 2000 | 45.0 | 20000 | 10 | 30 | 21000 |

| SG-40 | 8740×5200×3220 | 2500×8360 | 1800 | 2500 | 55.0 | 24000 | 16 | 45 | 24500 |

| SG-62 | 12820×5200×3220 | 2500×12440 | 2800 | 4000 | 90.0 | 40000 | 24 | 60 | 31000 |

Mode |

glass bottle | Plastic bottle |

Soft bag |

||||||

| 100ml | 250ml | 500ml | 100ml | 250ml | 500m | 100m | 250ml | 500ml | |

| SG-1.2 | 2016 | 990 | 544 | 1400 | 768 | 480 | 520 | 416 | 312 |

| SG-2.5 | 4032 | 1980 | 1088 | 2800 | 1536 | 960 | 1040 | 832 | 624 |

| SG-5 | 7868 | 3960 | 2160 | 5568 | 3260 | 2112 | 2160 | 1800 | 1440 |

| SG-13 | 14400 | 7840 | 4536 | 10584 | 6120 | 4200 | 4320 | 3600 | 2160 |

| SG-26 | 28800 | 15680 | 9072 | 21168 | 12240 | 8400 | 8640 | 7200 | 4320 |

| SG-32 | 36000 | 19600 | 11340 | 26460 | 15300 | 10500 | 10800 | 9000 | 5400 |

| SG-40 | 44800 | 24192 | 13248 | 32928 | 19584 | 12000 | 13440 | 11200 | 8960 |

| SG-62 | 67200 | 36288 | 19872 | 49392 | 29376 | 18000 | 20160 | 16800 | 13440 |

| Note: The load ig above is just for reference, the actual loading will bed ferent because of the load ng method and bote sizes | |||||||||

Based on the principle of moist-heat sterilization under counter pressure, Superheated Water Spray Sterilizers have been developed to meet the terminal sterilization needs of the pharmaceutical industry. These sterilizers are equipped with a water recirculation system that includes a sanitary pump and spray system to efficiently heat up and cool down the products intended for sterilization. They are particularly well-suited for sterilizing infusion products, blister-packed items, and large quantities of liquids contained in glass or plastic containers.

Our company manufactures superheated water spray sterilizers specifically designed for the pharmaceutical industry, ensuring compliance with relevant EN and DIN standards. Each unit is constructed with a circular inner chamber and a rectangular door. These units are equipped with a fully automatic control system, a user-friendly touch screen control panel, and a thermal printer, making machine operation extremely convenient for users.

Whether you need adjustments in dimensions, loading capacities, or control systems, we can deliver a tailor-made machine to suit your needs at a highly competitive price point.